Tyre Industry :Upcoming Trends , Indian Scenario & Michelien

The word tyre has been derived from the French word tirer meaning 'to pull'. Prior to the invention of pneumatic or air filled tyres, tyres were made up of bands of leather or iron placed on wooden wheels. This would protect the wheels of the carts and wagons from rapid wear and tear.

Evolution of Rubber Tyres:

the 1800's, Charles Macintosh experimented with sap from trees in Amazon area to create rubber. But, it could not withstand the weather extremities.

Charles Goodyear discovered vulcanised rubber in 1839, by adding sulphur, making it elastic and strong enough to be used as cushion tyres for cycles.

It was in 1845 that pneumatic or air filled tyres were invented and patented by Robert William Thomson, a Scottish inventor. His design had multiple thin tubes inside a leather cover, so that the tyre could absorb shocks (see illustration) . But, it never really went into production due to its severe limitations.

However, in 1888, John Boyd Dunlop from Ireland, came up with the first practical pneumatic tyre which later became Dunlop tyres. He also tested the first pneumatic or air-filled tyres on a tricycle and took it for a spin. Pneumatic tyres gained their popularity due to the growing use of bicycles in the late 18th century.

Indian Tyre Industry:

In 1926, Dunlop Rubber Limited became the first company in India to set up a tyre company in West Bengal. The MRF (Madras Rubber Factory Limited) followed its footsteps and entered the tyre manufacturing market in 1946 although it ventured into manufacturing tread rubber in 1952.

Today, the India tyre industry employs as many as one million people including dealers, retraders, and growers of natural rubber.

Indian tyre industry has almost doubled from Rs 30,000 crores in 2010-11 to Rs 59,500 crores in 2017-18 of which 90-95% came from the domestic markets. The top three companies – MRF, Apollo Tyres and JK Tyres have 60% of the market share in terms of revenue. In terms of segmentation tyres can be divided in two ways – based on end market and based on product.

Based On End Market

Replacement, OEMs & Exports

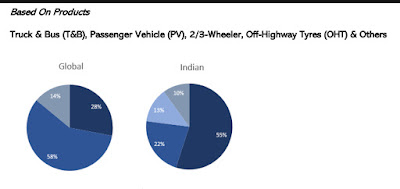

Based On Products

Truck & Bus (T&B), Passenger Vehicle (PV), 2/3-Wheeler, Off-Highway Tyres (OHT) & Others

T&B tyres in India generates the major revenue i.e. 55% of total revenue whereas globally it’s the PCR (Passenger Car Radials) contribute the largest portion of the revenue. This is mainly because of very low penetration of passenger vehicles in India – below 20 per 1,000 people whereas in China the number is 69 per 1,000 people and 786 per 1,000 people in US. In terms of volume (tonnage) T&B contributes around 50% of the total volume

The demand from OEM’s is widely spread across the segment where T&B contributed ~35% and PVs & 2/3 Wheeler’s contributed 25% & 22% respectively. In term of the replacement segment the demand was more skewed towards the T&B tyres which contributed ~61% and PVs & 2/3 Wheeler’s contributed 14% & 9% respectively.

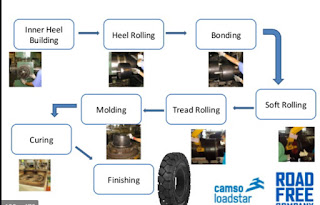

Manufacturing Process :

A simple round looking tyre is manufactured by complex assembly of more than 250 raw materials amongst which the major components include natural & synthetic rubber, nylon tire fabric, bead wire, carbon black, reinforcing non-black fillers like silica, vulcanizing agents & anti-oxidants.

The process begins with the mixing of basic rubbers with process oils, carbon black, pigments, antioxidants, accelerators and other additives, each of which contributes certain properties to the compound.

These ingredients are mixed in giant blenders called Banbury machines operating under high heat and pressure. They blend the many ingredients together into homogenized batch of black material with the consistency of gum. The mixing process is computer-controlled to assure uniformity. The compounded materials are then sent to the next stage of processing for further processing into sidewalls, treads or other parts of the tyre.

Then the task of assembling the tyre begins. The first component to go on the tyre building machine is the inner liner, a special rubber that is resistant to air and moisture penetration and takes the place of an inner tube. Next comes the body plies and belts, which are often made from polyester and steel – Plies and belts give the tyre strength while also providing flexibility. The belts are cut to the precise angle and size specified by the tyre engineer to provide the desired ride and handling characteristics.

Bronze-coated strands of steel wire, fashioned into two hoops, are implanted into the sidewall of the tyres to form the bead, which assures an airtight fit with the rim of the wheel. The strands are aligned into a ribbon coated with rubber for adhesion, then wound into loops that are then wrapped together to secure them until they are assembled with the rest of the tyre.

Radial tyres are built on one or two tyre machines. The tyre starts with a double layer of synthetic gum rubber called an inner liner that will seal in air and make the tyre tubeless.

Then, come two layers of ply fabric, the cords – two strips called apexes stiffen the area just above the bead. Next, a pair of chafer strips is added to resist the chafing from the wheel rim

when mounted on a car.

|

| (Courtsey B. Standard ) |

|

| Courtsey B.Standard |

The tyre building machine pre-shapes radial tyres into a form which is very close to their final dimension to check whether components are placed in proper position before the tyre goes into the mold.

Now the tyre builder adds the steel belts that resist punctures and hold the tread firmly against the road. The tread is the last part to go on the tyre and is pressed firmly together by automatic rollers. The end result is called a “green” or uncured tyre, ready for inspection and curing.

The curing press is where tyres get their final shape and tread pattern. Hot molds like giant waffle irons shape and vulcanize the tyre. The molds are engraved with the tread pattern, the sidewall markings of the manufacturer.

Tyres are cured at over 300 degrees for 12 to 25 minutes, depending on their size. As the press swings open, the tyres are ejected from their molds onto a long conveyor belt that carries them to final finish and inspection bay.

Cost Structure :

Tyre Industry is known for its capital-intensive structure where 60% to 65% of the revenues is raw material cost. The other important cost involved are SG&A (selling general & administrative) which roughly contribute from 6% to 12% of the revenues and employee cost contributing from 7% to 14% of revenues.

The Incredible story Of Michelien

1914 Aircraft

Michelin joined in the war effort by building Breguet airplanes in its factories.

1916 Aviation

Michelin built the world’s first paved runway in Clermont Ferrand.

1922 A car for everyone

Michelin commissioned a market survey entitled “The National People’s Automobile Survey” The aim was to collect data on consumer needs to draw up a design brief for a new, more versatile and, above all, more affordable automobile. The result was the Citroën 2 CV.

1929 The Micheline

Michelin invented the “Micheline” railcar with its innovative pneumatic tires.

1935 Citroën

Michelin acquired a controlling interest in French car maker Citroën, which it held until 1975.

1937 The METALIC tire

Michelin invented the first steel casing tire for trucks: the METALIC.

1946 The radial tire

Michelin filed a patent for the revolutionary “Radial” tire.

1952 Radial technology

Michelin adapted its Radial technology for truck tires.

1959 The first radial earthmover tire

Michelin introduced the first Radial tire for earthmovers.

1965 Test centers

Michelin inaugurated its Ladoux Testing and Research Center located to the north of Clermont-Ferrand. Michelin went on to open more test centers across the globe: Laurens in South Carolina and Almeria in Spain in 1977 then Ota in Japan in 1991 followed by Thailand, China, South America and India.

1973 A WRC win

Michelin was the first winner of a new type of race: the World Rally Championship (WRC) created by the Fédération Internationale Automobile (FIA) in 1973. It partnered with the Renault-Alpine team. That year, Michelin set up its Motorsport department.

1975 America, here we come

Michelin opened its first US plant in Greenville, South Carolina to manufacture Radial tires. Other plants soon sprang up: Anderson (1975), Spartanburg (1978) and Dothan (1979).

1979 Formula 1

Following its first Grand Prix win in 1977 with Renault and Jean-Pierre Jabouille, the MICHELIN radial tire became the Formula 1 World Champion sharing the honors with Ferrari. After an impressive track record – 102 wins, 5 drivers’ titles and 4 constructors’ titles – Michelin decided to withdraw from Formula 1 racing.

1981 MICHELIN Air X

Michelin developed the Michelin X Air, the first Radial aircraft tire.

1981 Acquisition

The Kléber tire company became part of the Michelin Group.

1983 MotoGP

A Radial tire won a motorcycle championship for the first time. Freddie Spencer claimed victory with a Michelin Radial rear tire. The driver went on to win the Moto GP World Championships on Radial tires the following year. Michelin’s clocked up its 400th victory in 2018.

1987 The radial motorcycle tire

Michelin launched its first Radial motorcycle tire.

1990 Acquisition

The Uniroyal-Goodrich Tire Company became part of the Michelin Group which had now reached the critical size to secure its future in North America.

1992 The low rolling resistance tire

Michelin launched the first low rolling resistance tire, the forerunner to the MICHELIN EnergyTM range released in 1994.

1995 Stomil-Olsztyn

The Polish tire manufacturer Stomil-Olsztyn became part of the Michelin Group. The next year, a Hungarian company, Taurus, came on board.

1996 Michelin looked East

After setting up the Michelin Shenyang Tire Company in 1995, the Group opened production facilities in the province of Shenyang.

1998 Michelin Challenge Bibendum

To mark the centenary of the Michelin Man, the Group hosted an event to showcase “clean” vehicle technology: the Michelin Challenge Bibendum. The event became a regular fixture with twelve challenges being held between 1998 and 2014 in the US, China, Japan, Brazil and Germany etc. The Challenge was given a new lease of life in 2017 when it became the Movin’On by Michelin Global Sustainable Mobility Summit in 2017.

2000 The Michelin Man: Best brand icon of all time

The Michelin Man was voted the best brand icon of all time by a jury of advertising professionals for the Financial Times. His shape and style have changed several times over the years. To celebrate his 120th birthday, he got another more modern makeover unveiled in 2018.

2001 Innovations

Michelin developed the MICHELIN XDR, the world’s biggest earthmover tire and set up ViaMichelin.

2001 Acquisition

Michelin became a leader in China with the creation of the Shanghai Michelin Warrior Tire Co. and in Romania with the acquisition of two Tofan plants.

2004 A corporate tagline

Michelin adopted a global corporate tagline illustrating its pledge to achieve better, more efficient and more environmentally-friendly mobility: “Michelin: a better way forward”

2005 Michel Rollier

Michel Rollier became Managing Partner in 2005 and from 2006, after the accidental death of Édouard Michelin, managed the company alone.

2012 Jean-Dominique Senard

Jean-Dominique Senard who had been one of the Managing Partners since 2007 became the sole Managing Partner of the Michelin Group. Two large plants opened in Brazil and China.

2014 Formula-E

Since 2014 electric cars have been racing on Michelin tires in the Formula E single-seater street racing championship. Michelin engineers developed a tire that was both versatile and durable, capable of lasting an entire race day: the MICHELIN Pilot Sport EV. The tire measured 18 inches and bore a close resemblance to the tires found on a prestigious sports car.

2014 acquisition

Michelin finalized the acquisition of SASCAR, the leading Brazilian digital fleet management and freight security company.

2015 MICHELIN CrossClimate

Michelin launched the MICHELIN CrossClimate, the world’s first summer tire also approved for winter use.

2016 Acquisition

Michelin bought out BookaTable, Europe’s biggest online restaurant reservation platform.

2017 Movin’on by Michelin

Michelin organized the first global Sustainable Mobility Summit in Montreal. Michelin showcased a revolutionary prototype of its Vision Concept tire.

2018 Icon of the millennium

The Michelin Man was named the icon of the millennium during Advertising Week in New York. A great 120th birthday present!

2018 Acquisition

Michelin bought out the Canadian company Camso, making the Group the world leader in off-the-road tires.

+ Fenner, May 2018.

2019 UPTIS

Michelin UPTIS, with its innovative and revolutionary technology, eliminates any risk of punctures.Unveiled by Michelin at the "Movin' On 2019" summit dedicated to sustainable mobility, Michelin UPTIS, the airless tire, represents a major innovation both in terms of safety and respect for the environment.

Top 5 Tyre Brands worldwide:

Michelin:

28th May 1889 was the day this French tire maker took birth thanks to the Michelin brothers; Edouard and Andre Michelin. Over the next century, Michelin made its mark as the second-largest tire brand in the world and earned itself the reputation for tire quality that delivers a confident driving experience. Le Mans and MotoGP; the 2 globally acclaimed motorsports organizations rely on their tires. Performance and durability is the reason for these tires’ reputation.

2. Pirelli

Giovanni Battista in the year 1872 founded Pirelli Milan. Taking the position of the 5th largest tire manufacturer in the world, they are well known to compliment supercars’ performance. But they do not limit themselves to supercars; they have established their standards in the 2 wheeler on-off road, passenger cars and SUVs on – off-road too. Interesting fact, they are the only tire makers that focus on tires particularly for 2 wheelers and PCRS only.

3. Cooper

Headquartered in USA , Ohio founded in 1914 they are primarily into manufacturing of tires for heavy vehicles.

4. Goodyear: Another American manufacturer, they are major competitors of Cooper Tyres and are known for affordable prices and high quality.

5. Continental: German Heavy Weight camel quite late into tire business they were earlier into heavy machinery and railways.

Future Trends of Tyre Industry:

Comments

Post a Comment